Tesla Model S: HV Junction Box - 1st Generation (Remove and Replace)

Warning: Only technicians who have been trained in High Voltage Awareness are permitted to perform this procedure. Proper personal protective equipment (PPE) and insulating HV gloves with a minimum rating of class 00 (500V) must be worn any time a high voltage cable is handled. Refer to Tech Note TN-15-92-003, "High Voltage Awareness Care Points" for additional safety information.

Removal

Note: The Slave charger is not installed on all vehicles, but it may appear in the graphics for this procedure.

- Perform the vehicle electrical isolation procedure (refer to procedure).

- Remove the HVJB cover (refer to procedure).

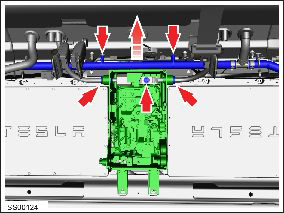

- Position the coolant hose aside to access to the HV junction box

bracket bolts.

- Release the clips (x2) that secure the charger coolant hose to the heel board.

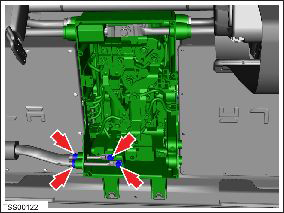

- Remove the bolts (x4) that secure the HV junction box (torque 5

Nm).

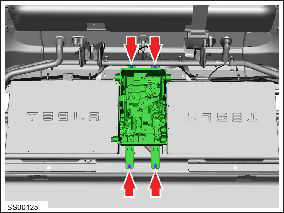

- Disconnect the junction box to slave charger connectors (x2). Note: Note installed position of components before removal. Note: Lower specification vehicles do not have this component installed.

- Disconnect the High Voltage Interlock (HVIL) loop connector and

position it aside.

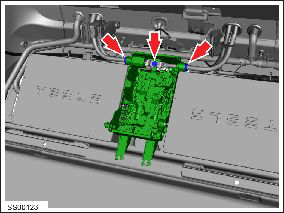

- Disconnect the junction box to master charger connectors (x5). Note: Note installed position of components before removal.

- Carefully lift the junction box and support it on a block to gain access to connectors.

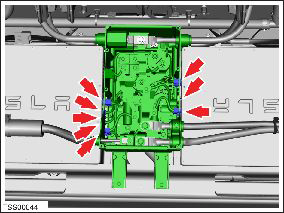

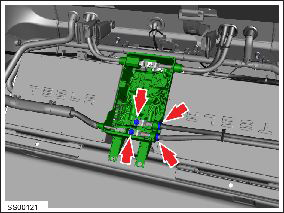

- Remove the bolts (x2) that secure the positive and negative charge port cables at the HV junction box (torque 9 Nm).

- Release the quick connectors (x2) that secure the charge port

cables to the HV junction box body, then move the cables aside.

- Remove the bolts (x2) that secure the DCDC positive and negative cable terminals to the HV junction box (torque 9 Nm).

- Release the quick connectors (x2) that secure the DCDC cables to

the HV junction box body, then move the cables aside.

- Remove the bolt that secures the drive inverter and HV battery positive cables to the HV junction box (torque 9 Nm).

- Release the quick connectors (x2) that secure the drive inverter

and HV battery positive cables to the HV junction box body, then

move the cables aside.

- Remove the bolt that secures the drive inverter and HV battery negative cables to the HV junction box (torque 9 Nm).

- Release the quick connectors (x2) that secure the drive inverter and HV battery negative cables to the HV junction box body, then move the cables aside.

- Remove the bolt that secures the ground strap to the HV junction box (torque 5 Nm).

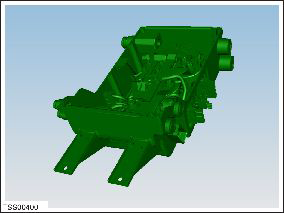

- Remove the HV junction box.

Installation procedure is the reverse of removal.