Tesla Model S: HV Junction Box - Cover - 2nd Generation (Remove and Replace) - Removal

Warning: Only technicians who have been trained in High Voltage Awareness are permitted to perform this procedure. Proper personal protective equipment (PPE) and insulating HV gloves with a minimum rating of class 00 (500V) must be worn any time a high voltage cable is handled. Refer to Tech Note TN-15-92-003, "High Voltage Awareness Care Points" for additional safety information.

Removal

- Disconnect 12V and HV power:

- Rear wheel drive (RWD): Refer to procedure.

- Dual Motor: Refer to procedure.

- Remove the 2nd row seat frame:

- Standard seats: Refer to procedure.

- Executive seats: Refer to procedure.

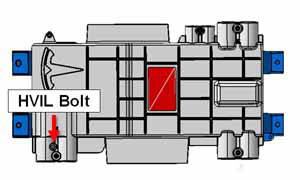

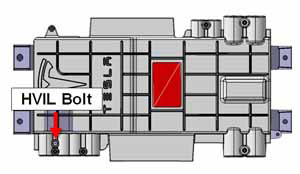

- Remove the HVIL bolt from the HVJB cover. Do not remove the

remaining fasteners at this time.

- North America, Japan (torque 4 Nm)

Note: In North American and Japanese vehicles, the HVIL bolt is one-time use only. Install a new bolt during reinstallation.

- Europe, APAC (torque 5 Nm)

Note: In European and APAC vehicles, the HVIL bolt can be reused during reinstallation.

- North America, Japan (torque 4 Nm)

Warning: Ensure that the multimeter and leads are capable of handling at least 500V.

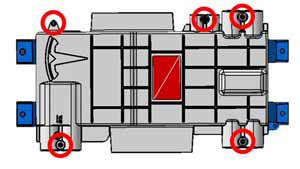

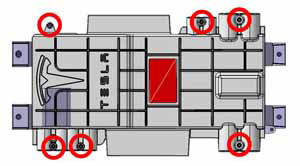

- Remove the remaining fasteners that secure the HVJB cover.

- North America, Japan (torque 8 Nm)

Note: In North American and Japanese vehicles, there are 5 additional fasteners.

- Europe, APAC (torque 8 Nm)

Note: In European and APAC vehicles, there are 6 additional fasteners.

- North America, Japan (torque 8 Nm)

- Use a multimeter to check voltages across the HV cables and to

ground:

Warning: If any voltage reading is more than 10V, the high voltage contactors are not fully opened. Due to the risk of electrocution, contact Service Engineering before performing any further work.

Warning: Never use a fastener or an e-coated surface as a path to ground. In this procedure, ensure that the ground strap from the HVJB is secure to the body and use the lug as a path to ground.

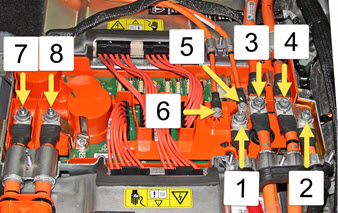

- The 4 HV cables to the HV battery and rear drive unit

- The 2 HV cables to the forward junction box

- The 2 HV cables to the charge port

- Dual Motor vehicles only: The 2 HV cables to the front drive unit

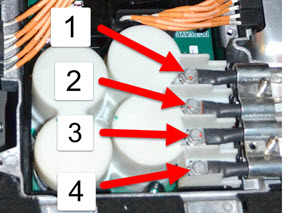

Note: Vehicles with 3-phase charging have 4 harnesses to the charge port:1 B+ Front Drive Unit (if equipped) 2 B- Front Drive Unit (if equipped) 3 B+ battery/drive inverter 4 B- battery/drive inverter 5 B+ DCDC converter 6 B- DCDC converter 7 B- charge port 8 B+ charge port

1 B+ N charge port 2 B- L1 charge port 3 B+ L3 charge port 4 B- L2 charge port